Tubulars Engineering

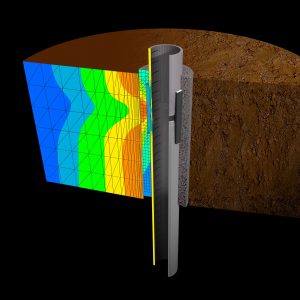

With deep roots in engineering fundamentals, Noetic maintains a large suite of highly customizable numerical models, a state-of-the-art facility for materials mechanical characterization and a flexible experimental services laboratory. We use these tools to characterize the limits of, and support selection and optimization of, pipe-connection systems for a wide range of subsurface oil and gas applications. From conventional applications to the most severe well environments, we support our clients with:

- Mechanical engineering evaluations that ensure candidate tubular configurations, connections and materials align with application demands

- Definition of tubulars design requirements for applications where standardized methods do not provide sufficient confidence

- Product assessments that align the right product with target well application, either using established evaluation protocols or customized evaluation methodologies

- Detailed field evidence reviews to understand the state and capacity of the tubular system for future operations

- Fundamental tubular systems research to close key industry technology gaps

VolantRED™ Real-time Tubular Monitoring

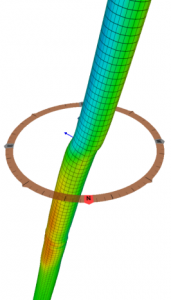

VolantRED™ Real-time Tubular Monitoring Wellbore Inspector™ Casing Deformation Interpretation

Wellbore Inspector™ Casing Deformation Interpretation